Patina Colors & Metals

Patinas are the finishing touch to our handcrafted lights—the decorative colors and textures that make every piece a work of art. In their natural state, most metals combine with chemicals in the earth or air to create metallic compounds that change their surface color, which appear as rust or tarnish. These thin layers of corrosion are nature's patinas. Since ancient times, craftspeople have used the corrosive property of metal to produce aesthetically pleasing color on it surface—sometimes resorting to burying or exposing metal for many years to achieve the desired patina.

Today, artisans have much faster and more efficient methods for producing a wide range of color and texture. Among the most common procedures are immersion and spraying. During immersion, a piece is cleaned with sandblasting or chemicals, then dipped into a prepared liquid compound, creating an immediate change in color. Alternatively, a piece is sprayed or brushed with a patina solution, allowed to air dry, and spritzed again. This oxidation process creates corrosion on the metal's surface that forms a layer of patina. Other methods include heat, dabbing and wiping, anodizing, and random contact patina.

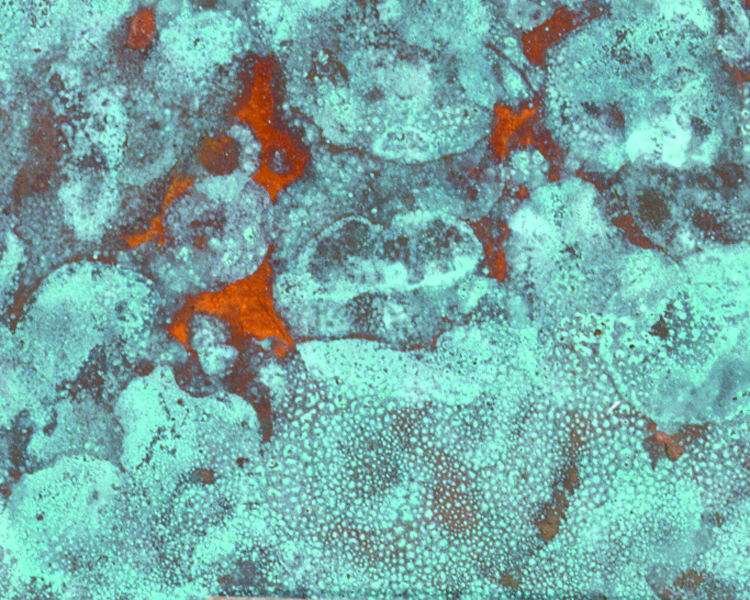

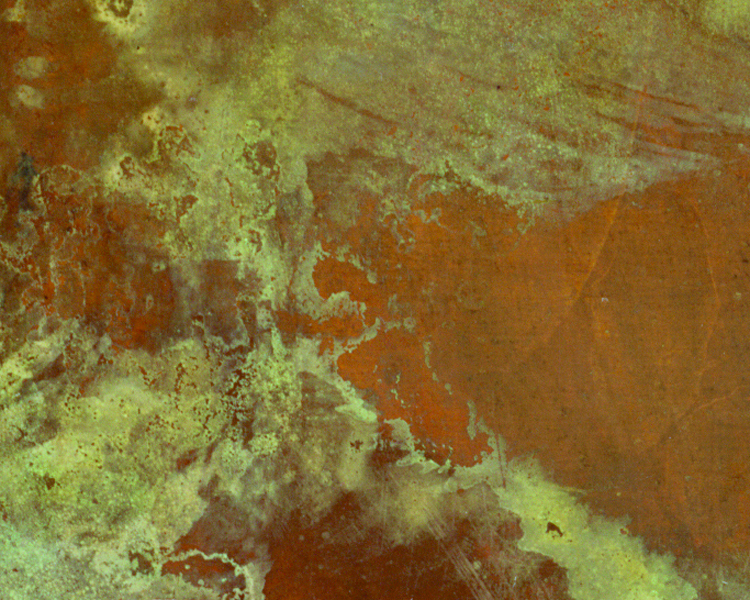

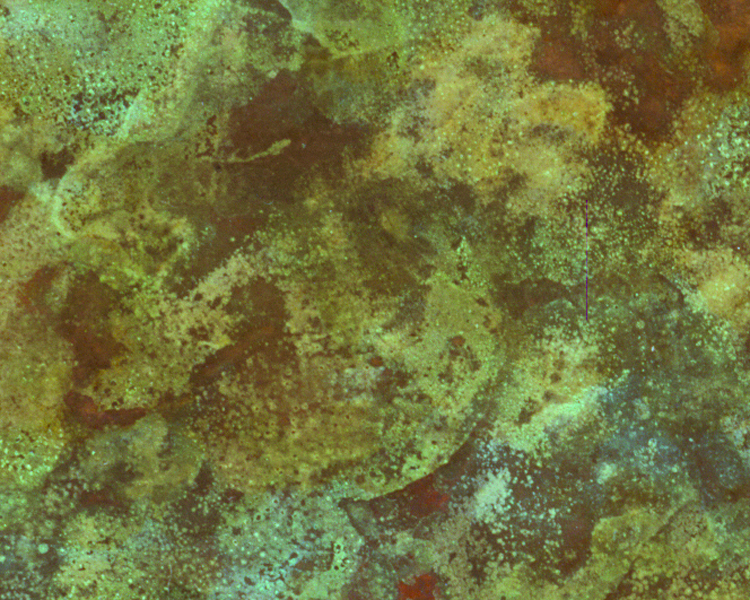

At Alchemy Lights, we employ several different methods to add an enticing variety of attractive patinas to copper, brass, and tin fixtures. Since the nature of oxidation makes patination unpredictable and every patina is hand applied, natural variance ensures that each piece is a unique treasure.

Patina Colors

Dark Bronze

Burnished Brass

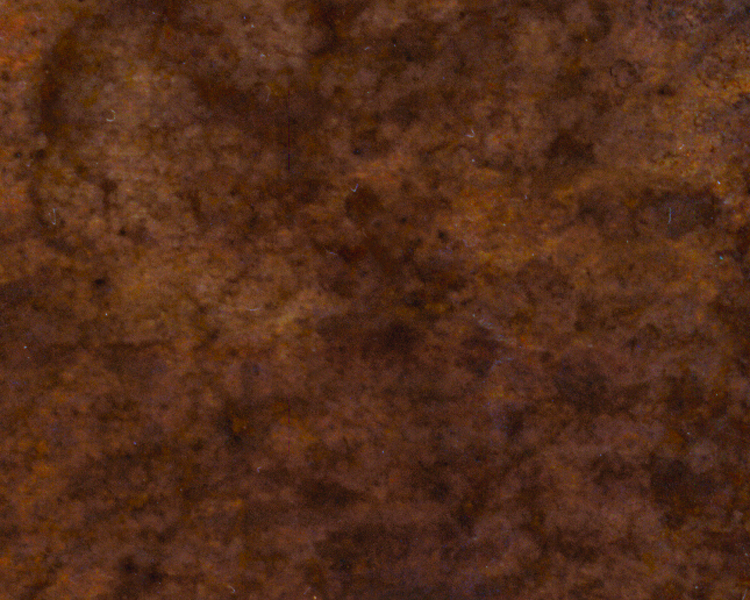

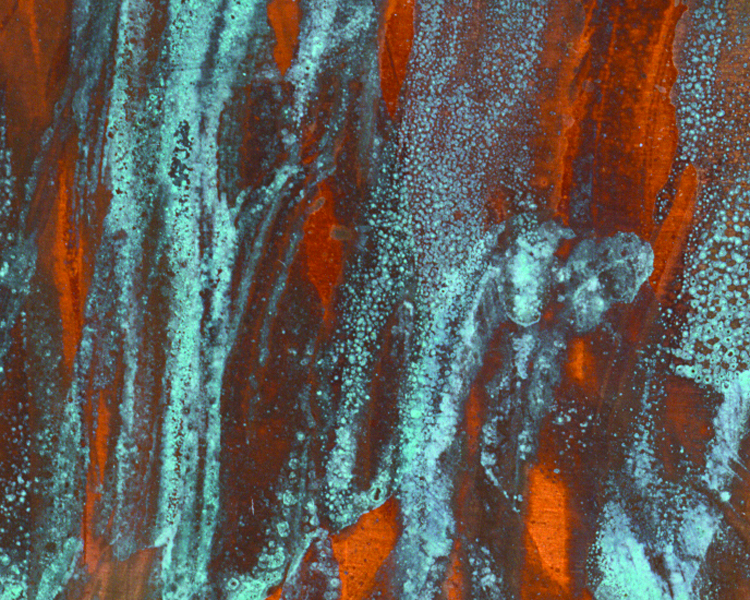

Rusty

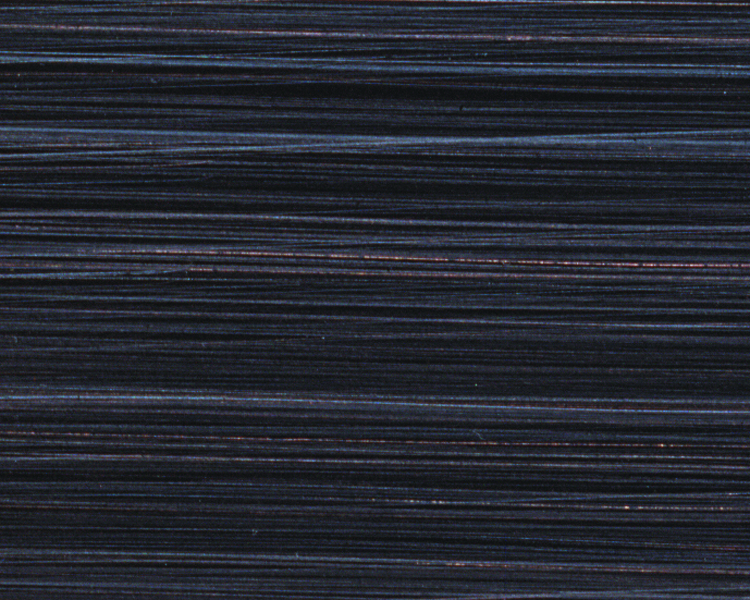

Iridescent

Hint of Brass

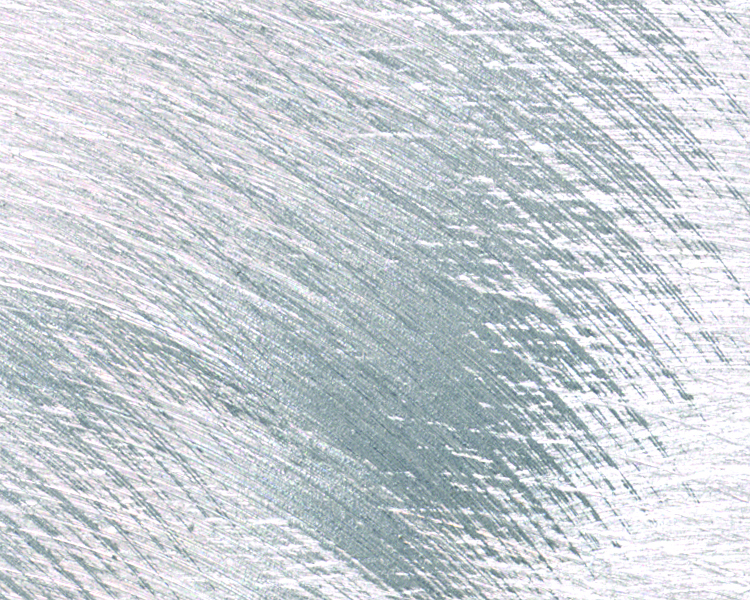

Pro Aluminum

Burnished Copper

Black Dots

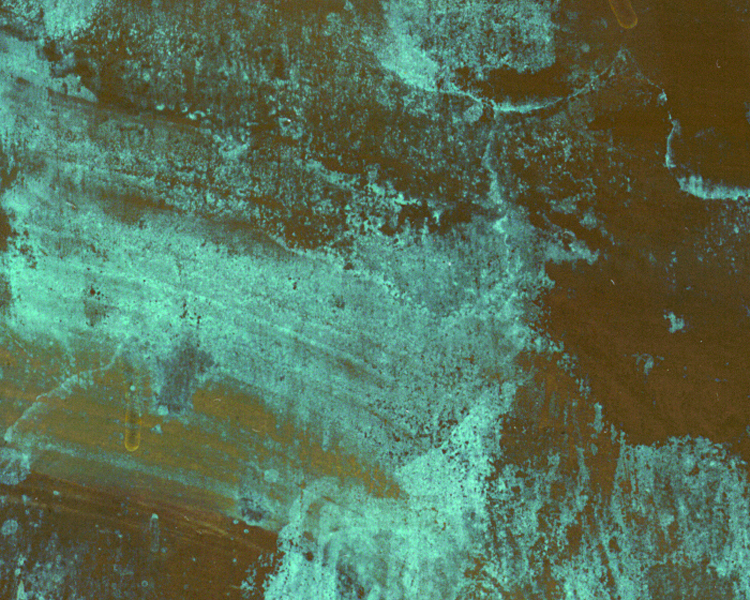

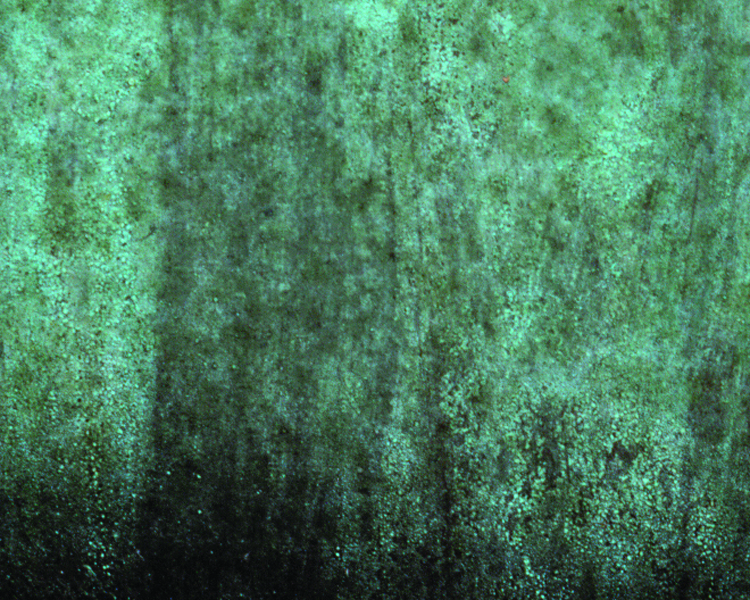

Green

Hint of Green

Light Bronze

Black Desert

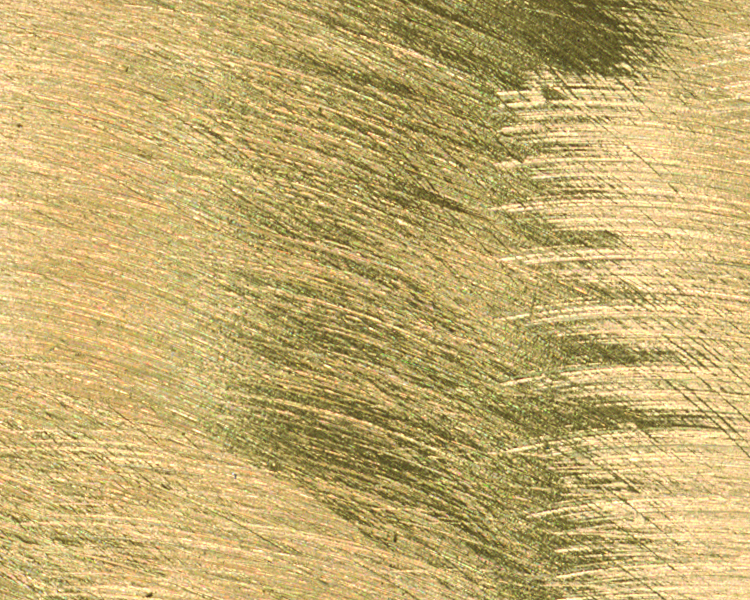

Pro Brass

Desert

Moss

Medium Bronze

Streak Green

Black Shadow

Ferric

Aged Tin

Metals

Copper's warm red-orange glow, malleability, durability, and beauty have made it one of the world's most sought-after metals. In fact, this ancient metal has been used to create both functional and decorative items for over 10,000 years.

At Alchemy Lights, we use copper as our primary metal for all styles of lighting. Customers love the way the ruddy incandescence of copper creates a sophisticated yet comfortable atmosphere in any room or outdoor space.

Copper

Aluminum

Brass